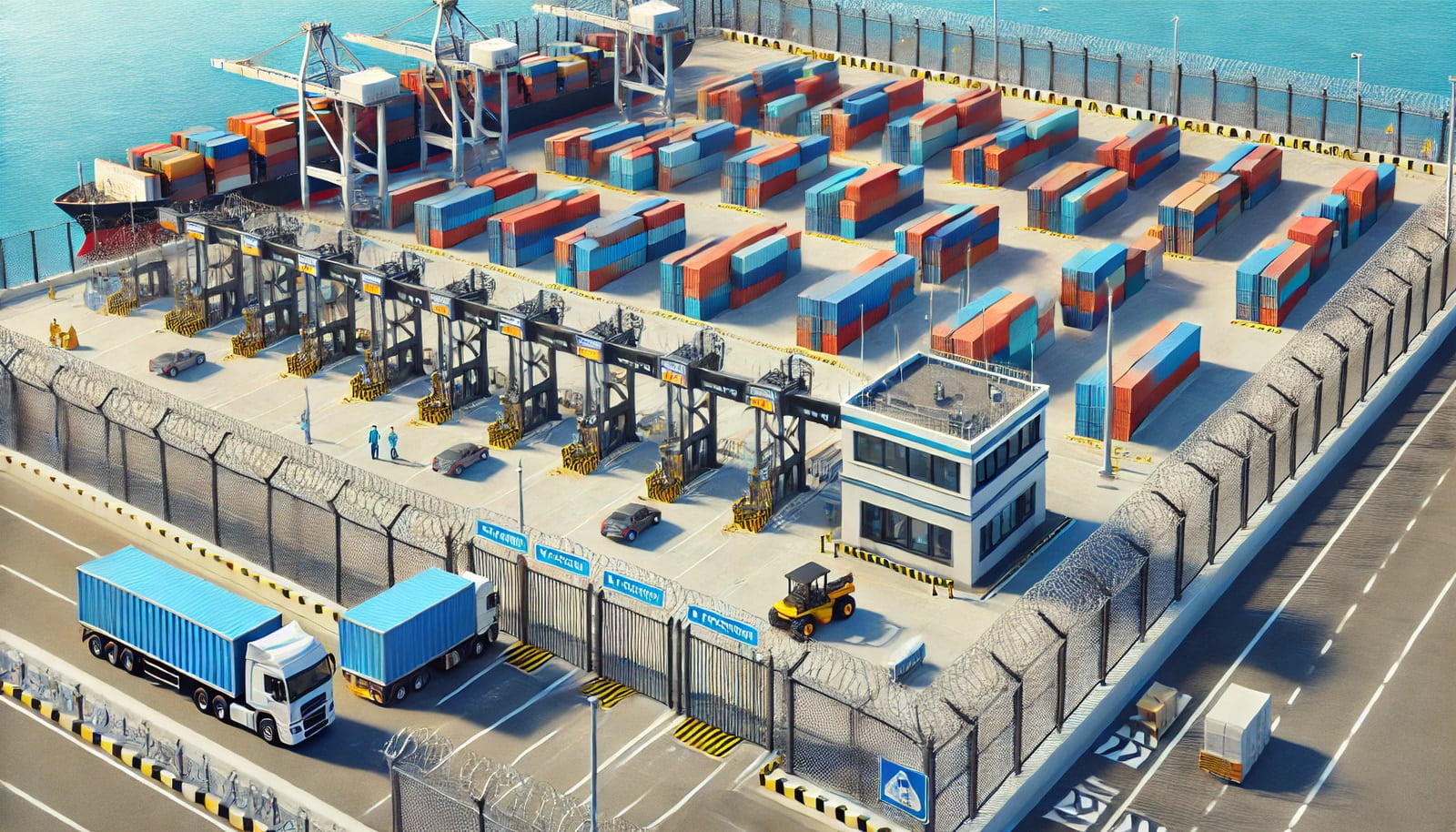

Shipping container terminals are critical hubs in the global supply chain, facilitating the efficient movement of goods across continents. However, they are also complex environments where safety is a major concern. From heavy machinery operations to the movement of massive containers, the potential for accidents and injuries is high. This article explores various strategies for improving safety in container terminals, as well as the benefits and challenges associated with implementing these measures.

1. Technological Advancements for Enhanced Safety.

One of the most effective ways to enhance safety in shipping container terminals is through the integration of technology. Automated systems and innovative solutions can significantly reduce human error and improve overall safety.

- Automation of Equipment: Automation of cranes, gantries, and other heavy equipment can minimize the need for manual handling, which is a common source of accidents. Automated systems can precisely control the movement of containers, reducing the likelihood of collisions and mishandling.

- Use of Drones for Inspection: Drones equipped with cameras and sensors can inspect high or hard-to-reach areas, such as crane structures or container stacks, without exposing workers to risky heights. They can also quickly monitor areas for safety hazards, providing real-time data.

- AI and IoT Integration: Artificial Intelligence (AI) and Internet of Things (IoT) technologies can monitor the entire terminal, using real-time data to predict and prevent accidents. For example, AI can alert operators when machinery shows signs of malfunction, while IoT devices can monitor environmental factors like weather conditions and air quality, reducing risks to workers.

- Increased accuracy and efficiency in terminal operations.

- Reduction in workplace accidents due to automated handling.

- Real-time monitoring and predictive maintenance minimize downtime and safety risks.

Drawbacks:

- High implementation costs for advanced technology.

- Requires workforce training and potential job displacement for manual labor roles.

- Dependence on technology introduces new risks, such as cybersecurity threats or system failures.

2. Improved Safety Training Programs.

No matter how advanced the technology, human operators and workers remain a crucial component of container terminal operations. Comprehensive safety training is essential to ensure all personnel are equipped with the knowledge and skills needed to maintain a safe working environment.

- Simulation Training: By using simulators, workers can practice operating heavy machinery in a controlled environment before they interact with real equipment. Simulations can also replicate various emergency scenarios, helping workers to respond appropriately when real incidents occur.

- Regular Safety Drills: Conducting routine safety drills ensures that employees are familiar with emergency procedures, such as evacuations, fire response, or handling chemical spills. These drills should be tailored to specific terminal environments to address unique hazards.

- Certification Programs: Requiring certifications for operating machinery and handling hazardous materials ensures that only qualified personnel undertake such tasks. Continuous education and refresher courses keep workers updated on best practices and new safety regulations.

Benefits:

- Enhances workers’ ability to respond effectively to emergencies.

- Builds a safety culture within the workforce, reducing the likelihood of accidents.

- Certification and training programs create a more professional and skilled workforce.

Drawbacks:

- Requires investment in training infrastructure and resources.

- Training can be time-consuming and might disrupt operations temporarily.

- Relies on worker commitment and retention to ensure the effectiveness of programs.

3. Improved Physical Infrastructure and Safety Equipment.

Upgrading and maintaining physical infrastructure is fundamental to enhancing safety at shipping container terminals. A properly designed and well-maintained infrastructure minimizes risks associated with container handling and movement.

- Barrier Systems: Installing physical barriers and guardrails in high-risk areas, such as around container stacks and alongside vehicle pathways, can protect workers from accidental collisions and falling containers.

- Safety Lighting and Markings: Proper illumination is critical for nighttime operations, as poor visibility can lead to accidents. High-visibility markings on pathways, vehicle lanes, and equipment create clear boundaries and reduce confusion, particularly in busy or restricted areas.

- Personal Protective Equipment (PPE): Ensuring that workers have access to high-quality PPE, such as helmets, high-visibility vests, gloves, and anti-slip boots, is essential. Employers must also enforce the use of this equipment to minimize injuries.

Benefits:

- Improved infrastructure reduces the risk of accidents related to poor layout or visibility issues.

- Safety barriers and markings create a more organized work environment.

- PPE provides direct protection to workers, lowering the severity of potential injuries.

Drawbacks:

- Infrastructure upgrades and maintenance can be expensive and require downtime.

- PPE compliance depends on worker discipline; inconsistent use can render these measures ineffective.

- Physical barriers may restrict maneuverability, potentially slowing down operations.

4. Enhanced Safety Monitoring and Incident Reporting Systems.

An effective safety monitoring system and robust incident reporting protocol are critical for addressing hazards promptly and learning from past incidents.

- Surveillance and Monitoring Systems: Installing cameras and sensors throughout the terminal can help monitor operations in real-time, ensuring safety standards are being followed. These systems can also track movement patterns to identify risky behaviors or areas prone to accidents.

- Digital Incident Reporting Platforms: Establishing a digital platform for incident reporting encourages prompt and detailed documentation of safety concerns or accidents. These platforms can be integrated with AI to analyze reports, detect patterns, and provide insights for proactive safety improvements.

- Wearable Safety Devices: Wearable technology, such as helmets with sensors that detect impact or exoskeletons that reduce physical strain, can provide an extra layer of safety for workers. These devices can alert supervisors if a worker falls or experiences hazardous conditions, enabling rapid response.

Benefits:

- Real-time monitoring systems allow for immediate intervention when safety rules are violated.

- Data-driven insights help identify and mitigate safety risks before they escalate.

- Digital systems streamline the reporting process, making it easier to track and address incidents.

Drawbacks:

- High initial investment and maintenance costs for advanced monitoring systems.

- Privacy concerns among workers regarding constant surveillance.

- Over-reliance on technology could result in gaps when systems fail or require maintenance.

Conclusion.

Improving safety in shipping container terminals requires a multi-faceted approach that balances technology, training, infrastructure, and monitoring systems. While the implementation of these safety measures brings numerous benefits, including a reduction in accidents and increased operational efficiency, challenges such as high costs and technological dependency must be carefully managed. By integrating these strategies thoughtfully, terminal operators can create safer working environments that benefit both their employees and the broader supply chain.

By proactively addressing safety concerns, the shipping industry can ensure that container terminals remain vital, efficient, and secure hubs in the global economy.