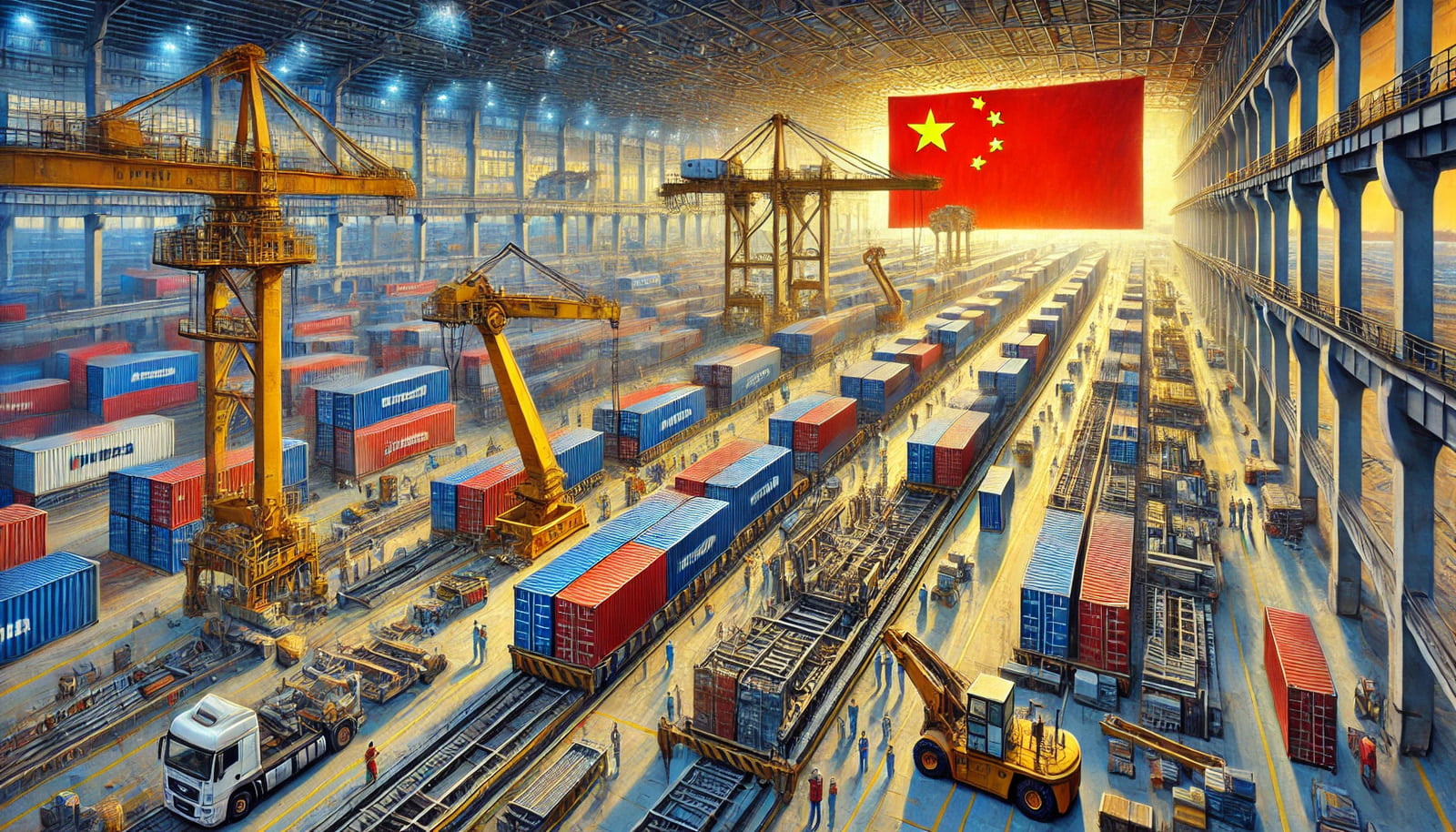

Over the past few decades, China has emerged as the global leader in manufacturing shipping containers. The country now produces more than 90% of the world's containers, a dominance that reflects not only China’s growing industrial power but also its strategic decisions in building infrastructure, technological development, and supply chain networks. Understanding why China has come to dominate this critical industry reveals important insights into both the global economy and China’s role within it. Here are the key factors that explain China's rise as the primary manufacturer of shipping containers.

1. Economies of Scale and Cost Efficiency.

One of the most critical reasons for China’s dominance in container manufacturing is its ability to leverage economies of scale. Chinese factories operate on a massive scale, producing containers at a lower cost per unit than their competitors. This scale advantage allows them to spread fixed costs, such as infrastructure, machinery, and labor, over millions of containers, reducing the overall production cost.

Additionally, China’s manufacturing industry benefits from lower labor costs compared to many Western countries. The cost of skilled labor in China has traditionally been much lower, enabling Chinese manufacturers to offer competitive pricing while still maintaining profitability.

2. Proximity to Raw Materials.

Steel is the primary material used to make shipping containers, and China is the world’s largest producer of steel. Chinese manufacturers have direct access to an abundant supply of domestically produced steel, which allows them to significantly reduce transportation and import costs associated with raw materials. This proximity to steel production has given China an enormous advantage over countries that need to import steel or rely on fluctuating international prices.

By sourcing materials domestically, Chinese manufacturers also gain greater control over their supply chain, allowing them to respond quickly to changes in global demand without worrying about long lead times or disruptions in supply.

3. Government Support and Industrial Policies.

The Chinese government has played a key role in nurturing the container manufacturing industry. Over the years, the government has provided substantial support to the manufacturing sector through subsidies, tax incentives, and favorable policies aimed at boosting production capacity. This support has enabled Chinese container manufacturers to invest in advanced machinery, improve production processes, and keep their pricing competitive on the global market.

China’s strategy of promoting manufacturing as a central pillar of its economic growth has also resulted in investments in transportation infrastructure, logistics, and shipping. This has made China not only a manufacturing hub but also a critical node in global shipping and trade networks, further boosting its container industry.

4. Technological Advancements and Innovation.

Chinese manufacturers have invested heavily in modernizing container production. Automation, digital tools, and robotics have transformed the manufacturing processes in China’s container factories. This shift toward technology-driven production allows manufacturers to improve the quality and durability of containers while simultaneously lowering costs and increasing output.

Moreover, Chinese companies have innovated in the design and engineering of containers, producing specialized containers for refrigerated goods (reefer containers), liquids, and other non-standard cargo. This ability to diversify their product offerings has further cemented China's position as the go-to source for shipping containers worldwide.

5. Strategic Location in Global Trade Routes.

China’s geographic location gives it a strategic advantage in container manufacturing. Located along critical global shipping routes, Chinese manufacturers can quickly ship containers to ports around the world. China’s access to major shipping lanes in the Pacific and Indian Oceans allows it to meet the logistical needs of both regional and international markets efficiently.

Furthermore, China’s investment in ports and maritime infrastructure ensures that its container manufacturers are closely linked to major shipping hubs. This strategic integration of manufacturing and shipping infrastructure creates a seamless supply chain, ensuring that the production, delivery, and usage of containers happen with minimal friction.

6. Response to Global Demand for Trade and Shipping.

As global trade has expanded, the demand for shipping containers has grown exponentially, particularly in the last few decades. China's massive manufacturing capacity has allowed it to meet this increasing demand, especially during periods of global supply chain stress, such as the COVID-19 pandemic. The flexibility and responsiveness of Chinese manufacturers to scale production have reinforced their dominance in the global container market.

In addition, China’s dominance in global manufacturing means that many of the goods being traded internationally are produced in China. As a result, producing containers domestically and shipping them out with goods produced in the same country creates a highly efficient loop that reduces overall costs for exporters.

7. Competitive Pricing.

Finally, Chinese manufacturers are known for their ability to offer highly competitive pricing on shipping containers. With their vast production capabilities, access to raw materials, and government backing, Chinese manufacturers have been able to keep their costs lower than competitors in other countries. This pricing advantage has effectively eliminated much of the competition from countries like South Korea and Japan, which were once significant players in the container manufacturing space.

Conclusion.